Biomass Pellet Mill Drying Equipment - Triple Cylinder Dryer

✅High Efficiency & Energy Saving: 3-layer countercurrent heat exchange, thermal efficiency >75%, lower energy consumption and operation cost.

✅Precise Drying: VFD speed control + layered lifting, moisture deviation ±1%, meets pelleting standards.

✅Space-Saving & Easy Installation: Nested structure, 40% less floor space, integrated design for quick commissioning.

✅Durable & Easy Maintenance: Wear-resistant material, low failure rate for continuous operation, quick replacement of spare parts.

✅Wide Adaptability: Multi-raw material/heat source, standard dust removal, customizable.

Product Introduction

The Triple Cylinder Dryer independently R&D and produced by Xingye Environmental Protection is the core Biomass Pellet Drying Equipment supporting biomass pellet production. Designed to solve the industry pain points such as high humidity, wall sticking and uneven drying of biomass raw materials, it is an energy-efficient industrial drying equipment. Upgraded with three-layer cylinder nesting on the basis of the traditional single-cylinder dryer, the equipment has a thermal efficiency of more than 75%. Compared with traditional equipment, the drying efficiency is increased by 50% and the heat loss is reduced by 40%. It can accurately control the moisture content of biomass raw materials such as straw, sawdust, rice husk and coconut bran to the optimal granulation standard of 8%-12%, perfectly adapting to the large-scale drying demand of biomass pellet production lines. The equipment supports the adaptation of various heat sources such as biomass fuel, natural gas, coal combustion and factory waste heat, and can be custom-designed according to the customer's production site and raw material characteristics. It is widely used in biomass energy, agricultural waste comprehensive utilization and other fields, and is an essential core equipment to reduce the energy consumption of biomass pellet production and improve the quality of finished products.

Working Principle

The Triple Cylinder Dryer adopts a linked structure of "inner, middle and outer three-layer concentric cylinders", and the core realizes the unique "three in and three out, countercurrent heat exchange" process of biomass drying equipment, so that the biomass raw materials and hot air flow achieve maximum heat exchange. The specific working process is divided into three steps:

Material movement: Wet biomass raw materials enter the inner cylinder through the feeding device and move forward quickly under the stir-frying and pushing of the customized lifting plate; then enter the middle cylinder, the movement direction is reversed to extend the residence time of the raw materials; finally enter the outer cylinder, change direction again and move to the discharge port, and complete the cycle of "breaking-stirring-rebreaking" throughout the process to avoid raw materials sticking to the wall and caking.

Hot air flow movement: High-temperature hot air flow enters from the outer cylinder, forms countercurrent heat exchange with the material, passes through the outer, middle and inner three layers of cylinders in turn, fully absorbs the moisture of the raw materials, and then discharges up to the standard through the supporting dust and deodorization system without secondary pollution.

Heat exchange core: The nested design of the three-layer cylinder expands the contact area between biomass raw materials and hot air flow by more than 2 times and prolongs the contact time by 30%, making every part of heat fully act on the raw materials, fundamentally improving the drying efficiency and reducing energy consumption, which is also the core advantage of this industrial drying equipment different from traditional equipment.

Product Core Features and Advantages

High efficiency and energy saving, low operating cost: High-density thermal insulation materials are filled between the cylinders, and thermal insulation coating is installed on the outer layer, the air leakage rate is controlled at an ultra-low level in the industry, and the thermal efficiency is as high as more than 75%; the countercurrent heat exchange design makes the high-temperature area correspond to high-humidity materials to avoid energy waste. Compared with the traditional single-cylinder dryer, the standard coal consumption is only 6-8kg/t, and the power consumption is reduced by 60%.

Uniform drying, high quality of finished products: Each layer of cylinder is equipped with a special angle lifting plate, the inner layer is broken, the middle layer is stir-fried, and the outer layer is shaped. The material forms a dense "material curtain" to contact the hot air flow without dead angle, and the moisture deviation of the finished product is controlled within ±1%; the cylinder speed can be adjusted by frequency conversion, and flexibly adjusted according to the initial humidity of the raw material to avoid over-drying or excessive moisture.

Compact structure, small floor space: The nested design of three-layer concentric cylinders reduces the floor space by more than 40% compared with the traditional single-cylinder dryer, without large-scale civil transformation, and adapts to the site needs of old factory upgrading or new production line construction; the equipment is integrated and designed, the feeding, heat source, dust removal system are matched with the main body, the installation is convenient, and the commissioning cycle is shortened.

Stable and durable, low maintenance difficulty: The inner wall of the cylinder is made of wear-resistant alloy steel plate, and the lifting plate is equipped with anti-wear liner, which prolongs the service life of the equipment by 50%; the self-aligning supporting roller + double sealed bearing design is adopted, the failure rate is reduced by 30%, and it can run continuously for more than 800 hours; multiple inspection ports are reserved, and vulnerable parts can be quickly disassembled and replaced without professional technicians.

Environmental compliance, wide adaptability: Standard equipped with cyclone + bag type double dust removal system, the dust emission concentration is ≤10mg/m³, the feeding and discharge ports are designed with sealed type to avoid dust escape; it can handle a variety of biomass raw materials such as straw, sawdust, rice husk, coconut bran, and also adapt to the drying needs of slag, river sand, compound fertilizer raw materials, etc. The heat source can freely choose biomass fuel, natural gas, etc., to meet the resource conditions in different regions.

▉Product Technical Parameters

Model | Evaporation(T/H) | Power(KW) |

GHGΦ1.0×12×1 | 0.18-0.28 | 5.5+7.5+2.2 |

GHGΦ1.2×12×1 | 0.27-0.54 | 5.5+7.5+3 |

GHGΦ1.5×12×1 | 0.42-0.85 | 5.5+15+4 |

GHGΦ1.6×12×1 | 0.48-0.96 | 5.5+18.5+4 |

GHGΦ1.6×24×1 | 1.1-1.2 | 7.5+55+55 |

GHGΦ1.8×20×1 | 1.2 | 11+30+5.5 |

GHGΦ2.0×24×1 | 1.51-3.01 | 15+37+7.5 |

GHGΦ2.2×12×3 | 1.5 | 11+45 |

GHGΦ2.5×12×3 | 1.8 | 18.5+45 |

GHGΦ2.5×24×1 | 2.36-4.71 | 15+37 |

GHGΦ2.8×24×1 | 2.95-5.91 | 22+45 |

GHGΦ3.0×12×1 | 1.5 | 22+45+4 |

GHGΦ3.0×24×1 | 3.39-6.78 | 22+45 |

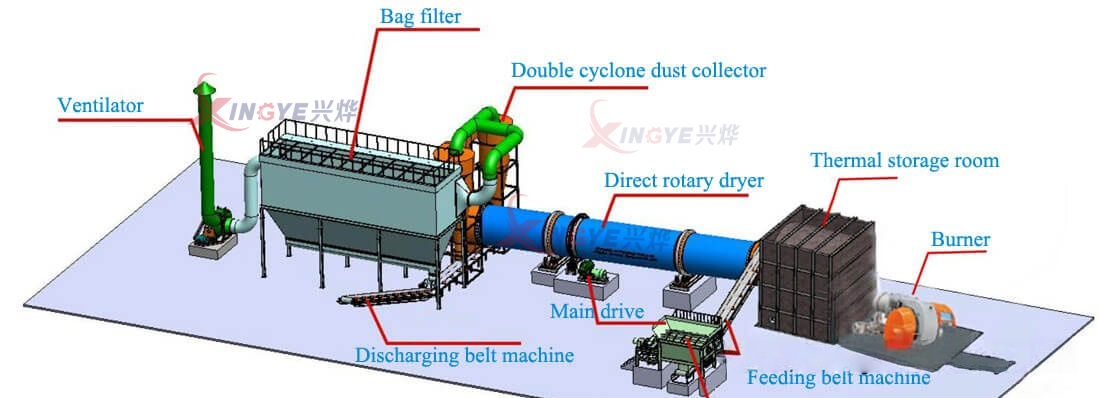

Production Line

Application Scenarios

As a professional biomass pellet drying equipment, this Triple Cylinder Dryer is core adapted to the raw material drying link of biomass pellet production lines, and can meet the drying needs of multiple industries at the same time. The core application scenarios are as follows:

Biomass energy industry: Drying of biomass raw materials such as straw, sawdust, rice husk, coconut bran, bamboo shavings, etc., providing up-to-standard raw materials for the production of biomass pellets and biomass fuel rods, adapting to the large-scale production of biomass energy plants.

Comprehensive utilization of agricultural waste: Drying of agricultural waste such as livestock and poultry manure, mushroom stick waste, etc., which can be made into organic fertilizer after drying to realize the recycling of agricultural resources.

Building materials/mining industry: Drying of river sand, quartz sand, slag, clay and other materials to meet the raw material moisture requirements of dry-mixed mortar, mineral processing and building materials production.

Chemical/compound fertilizer industry: Drying of compound fertilizer raw materials, sodium carbonate powder and other materials, precise temperature control to avoid changes in material properties and improve the qualified rate of finished products.

Company Introduction and Factory Strength

☆Xingye Environmental Protection Equipment Co., Ltd. is a high-tech enterprise focusing on the R&D, production, sales and after-sales of industrial environmental protection equipment. The core products cover a full set of biomass energy production equipment such as biomass pellet mill, Triple Cylinder Dryer, crusher, dryer, etc. With many years of experience in the production of foreign trade equipment.

☆The company has a standardized and modern production factory, equipped with a professional R&D and design team, precise production and processing equipment, and a strict quality inspection system. Every link from equipment design, raw material procurement to production and assembly is strictly controlled to ensure product quality. At the same time, the company has a senior technical service team, which can provide customers with one-stop services such as customized equipment solutions, on-site installation and commissioning, technical training, and lifelong after-sales maintenance, solving customers' production worries. We always adhere to the business philosophy of "Environmental Protection, High Efficiency, Innovation and Win-Win", and become the preferred partner of global customers for industrial environmental protection equipment with high-quality products and perfect services.

Shipment guarantee: After the equipment production is completed, it can be shipped only after strict commissioning and inspection Passed; standardized export packaging is adopted, and the vulnerable parts of the equipment are reinforced and protected to ensure no damage to the equipment during transportation; cooperate with world-renowned logistics enterprises, support sea, land, air and other transportation methods, and can choose the optimal logistics scheme according to customer needs to ensure the equipment is delivered on time and safely.

Customized service: Support the customized design and production of Triple Cylinder Dryer and supporting equipment according to the customer's raw material characteristics, production output, site size, heat source type and other needs, and provide the layout planning scheme of the whole production line.

After-sales guarantee: The equipment provides a 1-year free warranty,the technical team is online 7*24 hours to answer customers' technical questions in a timely manner.

Contact Us

If you are interested in our pellet mill equipment or would like to learn more about our delivery process, please feel free to contact us. We are committed to providing you with high-quality products and professional one-stop service.