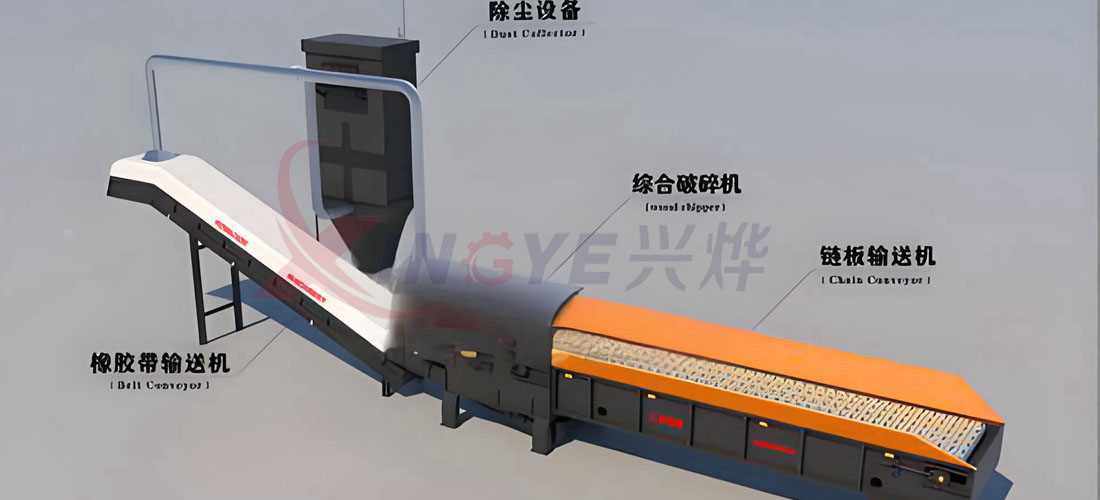

Industrial Biomass Comprehensive Wood Crusher

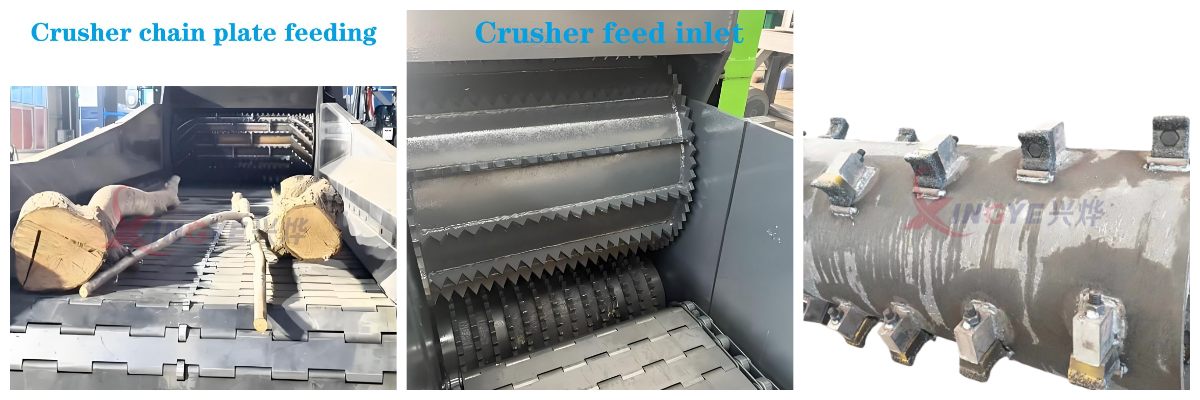

1.Dual-axis knife roller + hammer head combination design, crushing efficiency is 30% higher than traditional equipment, with a processing capacity of 5-20 tons per hour.

2.Built-in magnetic screening system, automatically separates metal impurities, avoids tool wear and prolongs service life.

3.Supports three installation methods: fixed, tire mobile, and crawler mobile, adapting to different site requirements.

4.Hydraulic cover opening system for easy maintenance, PLC intelligent control system for one-button start-stop and fault alarm.

5.Uses low-noise motors and sealed design to reduce dust and noise pollution, complying with EU environmental standards.

Product Introduction

The Biomass Wood Crusher is a professional Industrial Wood Shredder R&D and produced by Xingye Environmental Protection Equipment Co., Ltd. specially for the fields of biomass energy processing, wood recycling, industrial raw material treatment and so on. As a core High-efficiency Wood Crushing Equipment, it integrates environmental protection design and high-efficiency operation concept, and can carry out fine crushing treatment on various biomass wood materials such as round wood, branches, wood chips, plate leftover materials and straw. This Biomass Wood Crusher covers a variety of series models such as fixed and Mobile Wood Crusher, supporting customized crushing granularity with uniform discharge, which can be directly connected to the subsequent processing links such as pelleting, board making and combustion. It is a core Environmental Protection Wood Crushing Machinery for the biomass industry and wood processing industry to realize resource utilization and volume reduction of materials. All series of equipment are adapted to international general voltage standards , which can fully meet the actual needs of industrial production and environmental protection treatment of different customers around the world.

Working Principle

The Biomass Wood Crusher adopts the integrated continuous operation principle of "Feeding - Crushing - Screening - Discharging". The core transmission system is matched with a high-wear-resistant special motor, with strong power and stable operation without faults. After the materials enter the crushing cavity through the widened feeding port, they are sheared, impacted and ground by the combined structure of high-speed rotating blades and hammers to complete the initial crushing, and then accurately screened by the built-in grading and screening device of the equipment. The materials meeting the preset granularity requirements are automatically discharged through the discharge port, and the unqualified materials continue to be circularly crushed in the crushing cavity until they meet the operation standards.

This Industrial Wood Shredder is equipped with an intelligent overload protection device, which can automatically stop when hard objects such as metals and stones are mixed in the materials, effectively protecting the core components of the equipment from damage. At the same time, it adopts a fully sealed crushing cavity design and can be used with a dust removal device to realize dust-free leakage operation, which not only meets the industrial environmental protection requirements of various countries, but also greatly improves the on-site operation environment. The Mobile Wood Crusher is additionally equipped with a hydraulic lifting and traction moving device, which can flexibly adjust the feeding height and operation position without a fixed operation site, truly realizing on-site crushing and instant discharging and improving operation efficiency.

Application Scenarios

As a multifunctional biomass crushing equipment, the Biomass Wood Crusher has a wide range of application scenarios and can meet the material crushing needs of many industries:Biomass Energy Industry:

1.Biomass power plants, biomass pellet plants, biomass fuel processing plants, crushing round wood, straw, wood chips and other materials into qualified raw materials for the production of biomass pellets, biomass briquettes and direct combustion power generation.

2. Wood Processing Industry: Wood processing plants, board plants, furniture factories, crushing and recycling plate leftover materials, wood waste, shavings and other materials generated in the production process to realize secondary utilization of materials and reduce raw material costs.

3.Garden Sanitation Field: Municipal gardens, scenic spots, forest farms, carrying out on-site crushing of garden waste such as pruned branches, dead branches and fallen leaves to realize resource utilization of garden waste and reduce transportation costs.

4.Agricultural Field: Large farms, agricultural cooperatives, crushing agricultural waste such as crop straw and fruit tree branches for organic fertilizer processing, feed addition, etc., to realize comprehensive utilization of agricultural resources.

5.Waste Recycling Industry: Waste wood recycling companies, crushing recycled waste furniture, waste boards, construction square timber, etc., to facilitate transportation and reprocessing utilization.

Factory Strength

Xingye Environmental Protection Equipment Co., Ltd. has a standardized production equipped with advanced production equipment such as CNC cutting machines, large bending machines and precision milling machines, realizing independent production of core components and controlling product quality from the source. The company has a team of R&D engineers and technical workers with more than 10 years of industry experience, with independent product design, R&D and customization capabilities, and can quickly respond to the personalized needs of customers. A professional product quality inspection center is set up to carry out multiple tests such as no-load and load on each Biomass Wood Crusher delivered from the factory to ensure qualified factory delivery. It has a standardized finished product warehouse and logistics supporting, which can realize rapid stock preparation and delivery of equipment and ensure delivery time. The company has passed ISO9001 quality management system certification and CE EU product certification, with standardized production processes and guaranteed product quality, and is a reliable industrial environmental protection equipment supplier for global customers.

→Delivery Guarantee: Conventional models of Biomass Wood Crusher are in stock and will be arranged for delivery within 72 hours after payment. Customized models will be delivered on schedule according to the production cycle, and the production progress will be fed back in real time throughout the process.

→Perfect After-sales Service: Provide free equipment installation drawings, operation manuals and video tutorials; The whole machine of the equipment is guaranteed for 1 year.

→A 7×24-hour online after-sales service system is established, and global customers can consult by phone, email, WeChat and other methods. The after-sales team responds quickly to solve the equipment use problems of customers in a timely manner.

→We supply original factory parts of the equipment for a long time with reasonable prices and fast delivery to ensure the long-term stable operation of customers' equipment.

★If you are interested in our production,please contact us through the following channels.